Please send your design files, including 2D and 3D documents. This will help us analyse and quote your parts. If you have any other specifications or instructions, please include them as well.

After receiving your documents, our sales representative will contact you as soon as possible to provide an exact quote, and you to make an order after the price is confirmed.

After the parts are completed, we will immediately conduct quality inspections. Once the parts pass rigorous quality checks, we will promptly arrange for shipment.

Years of

Experience

Sino Die Casting, established in 2008, is a global leader in precision die casting solutions. The company specialises in the development and manufacture of precise components for the automotive, new energy, robotics, telecommunications, and general hardware industries. In Shenzhen, the company maintains an intelligent manufacturing base covering 12,000㎡, which has been verified by international standards including ISO 9001 and IATF 16949. It offers comprehensive, customised services to globally recognised organisations, such as BYD, Parker, Stanadyne, Sunwoda, and Eaglerise.

Cover Area

Monthly Capacity

Total Employees

Shipped Countries

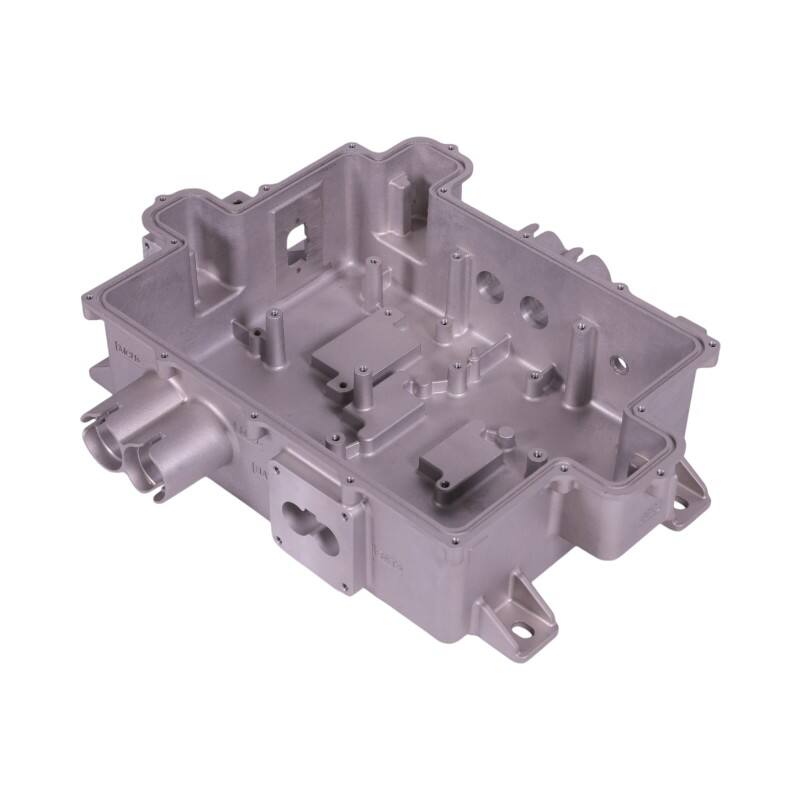

Sino Die Casting has a wide range of manufacturing capabilities, so you can be confident that all of your projects will be of high quality and reliable, owing to our facilities in China. We are ISO 9001 and IATF 16949 certified and provide complete solutions for custom die-casting parts.

Aluminum Die Casting Solutions for Automotive Transmission Systems

Aluminum Die Casting Solutions for Electronic Control System

Die cast Aluminum Housings for Automotive LED Driver Modules

Die cast Aluminum Enclosure for Telecommunications Industry

Aluminum Die Casting Solutions for New Energy Industry

Aluminum Die Casting Housing for Outdoor Lighting

We offer die casting solutions that are tailored to your industry's requirements, from functional parts to appearance components, all built with quality and performance in mind.

Automotive components must have tight tolerances, structural strength, and cost efficiency. We provide design flexibility and casting expertise to enable large-scale production of brackets, housings, and other structural components.

More InformationFor PV systems, we provide aluminum components (inverters, brackets, and frames) that meet stringent precision, weather resistance, and energy efficiency requirements. Our casting expertise and customized solutions enable consistent, high-volume production.

More InformationFrom industrial arms to surgical robots, we provide aluminum components that combine strength, precision, and lightweight performance while engineering for smooth motion and dependability.

More InformationWe manufacture aluminum enclosures, housings, and heat sinks for telecommunication systems. These components combine structural strength and thermal stability to offer reliable performance in compact, high-demand environments.

More InformationFor general hardware, we offer customized manufacturing and tailored surface treatments with various texture options. Our solutions boost durability, enhance aesthetics, and efficiently meet your exact requirements.

More Information

Automotive components must have tight tolerances, structural strength, and cost efficiency. We provide design flexibility and casting expertise to enable large-scale production of brackets, housings, and other structural components.

More Information

For PV systems, we provide aluminum components (inverters, brackets, and frames) that meet stringent precision, weather resistance, and energy efficiency requirements. Our casting expertise and customized solutions enable consistent, high-volume production.

More Information

From industrial arms to surgical robots, we provide aluminum components that combine strength, precision, and lightweight performance while engineering for smooth motion and dependability.

More Information

We manufacture aluminum enclosures, housings, and heat sinks for telecommunication systems. These components combine structural strength and thermal stability to offer reliable performance in compact, high-demand environments.

More Information

For general hardware, we offer customized manufacturing and tailored surface treatments with various texture options. Our solutions boost durability, enhance aesthetics, and efficiently meet your exact requirements.

More Information

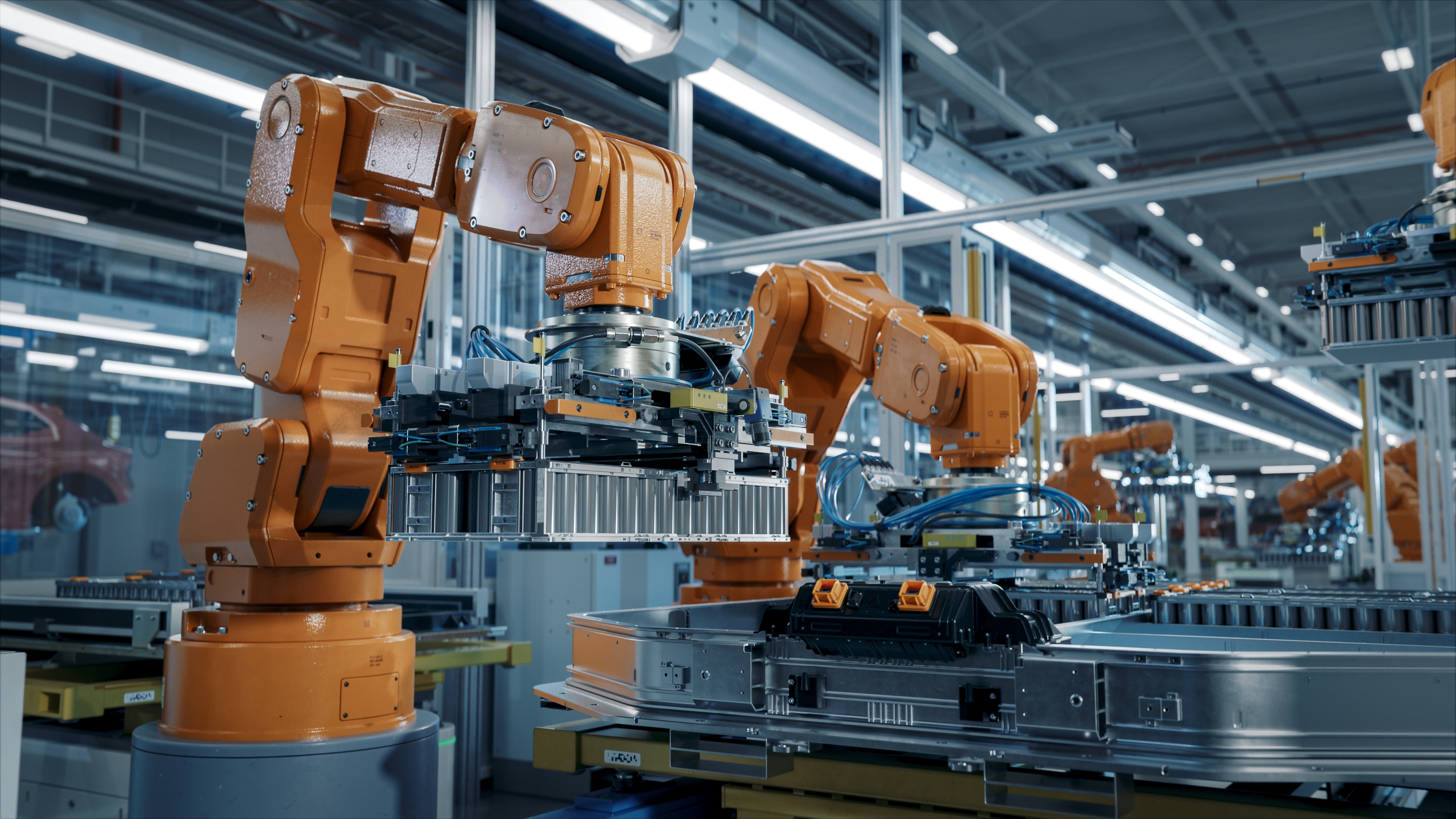

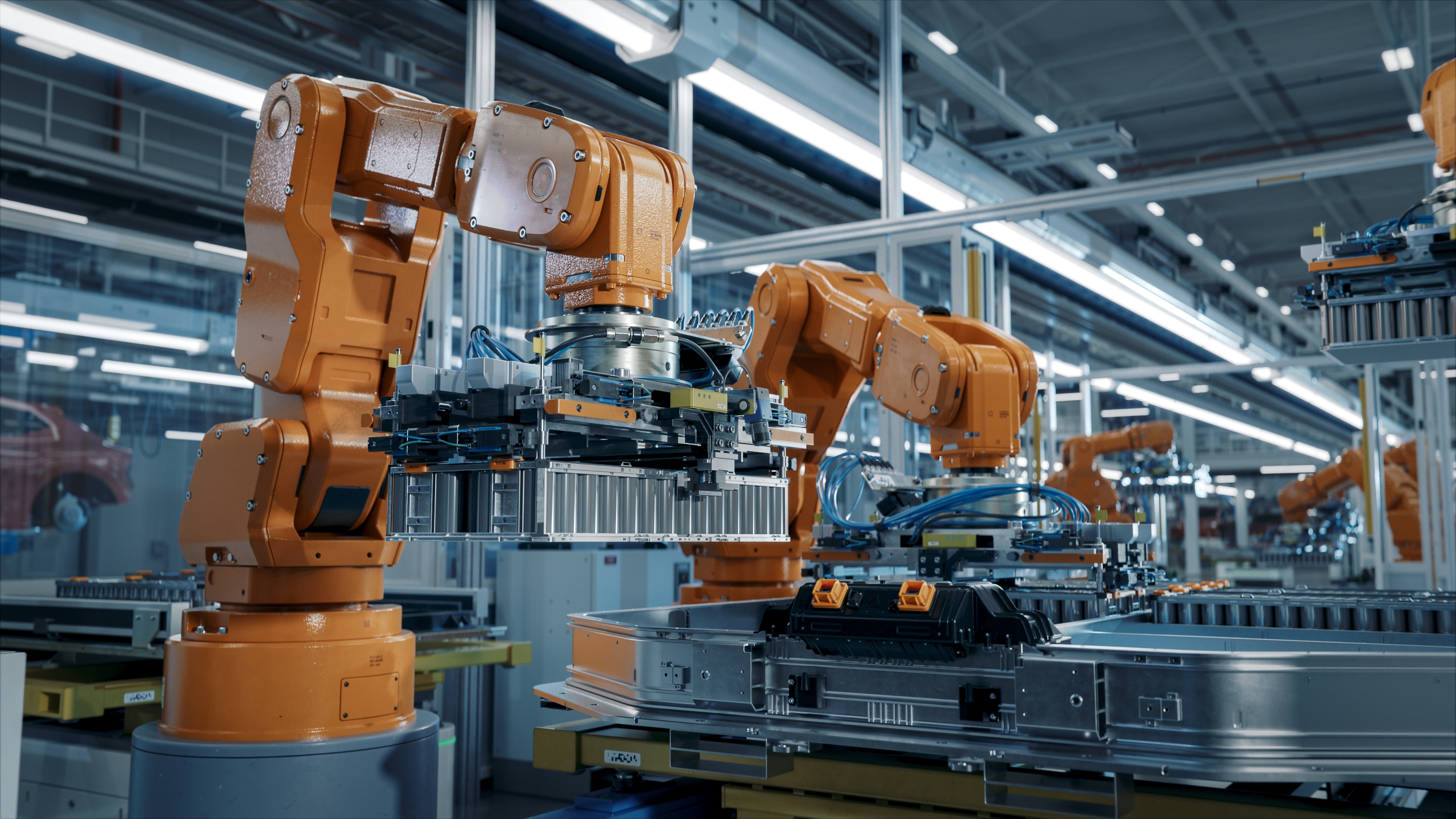

Certainly, our factory has production equipment such as cold chamber die casting machines (88T–1350T), CNC machining centers (3-axis, 4-axis, and 5-axis), mold manufacturing equipment, spraying production lines, and testing equipment. We are committed to providing high-quality manufacturing services, and having our own factory allows us to fully control the production process, ensuring the best results for our customers.

We are planning to expand our production equipment, add more die-casting machines and more CNC machining centers, upgrade fully automated production lines, and provide better services to our customers through upgrading equipment and production lines.

We have ISO9001, ISO14001, IATF16949, ISO45001, and IECQ QC080000 system certifications. We also strictly implement it internally to ensure that our production meets the highest industry standards. Actively obtaining certifications from well-known industry organizations is proof of our commitment to quality and excellence.

Yes, we have testing equipment such as coordinate measuring instruments, image measuring instruments, roughness instruments, salt spray testing instruments, spectral analysis instruments, etc. Support outputting inspection reports in English to meet your requirements for product size and functionality.

Sino Die Casting provides one-stop service to meet all your precision aluminum alloy and zinc alloy die-casting manufacturing needs. Support more than 15 types of processes, including mold design, mold production, die-casting, CNC machining, surface treatment, etc. We provide services ranging from mold design and manufacturing to product production and manufacturing, helping your products move from concept to mass production. By choosing SDC, you will gain a manufacturing partner that combines technological depth and service temperature, enabling innovative products to be introduced to the global market at a faster pace and with higher quality.

Here you can view the latest exhibition news and other recent information about the company.

13

On June 8, 2025, Sino Die Casting CEO George Lin led the team at the 11th Hardware Die‑Casting & Foundry Summit in Dongguan, engaging in smart, efficient, and low‑carbon manufacturing dialogues. Learn how Sino aligns for digital and green transformation.

Discover More05

Sino Die Casting upgrades to LK IMPRESS-III Series die casting machines, boosting efficiency and projecting a 30% annual production increase. Discover how we invest in advanced manufacturing technology to better serve global clients.

Discover More

Sino Die Casting 2026 Spring Festival Holiday Notice. Our factory will be closed from Feb 9 to Feb 23, 2026, and resume normal operations on Feb 24. Please plan your projects accordingly.